Eratech GmbH © 2024 All Rights Reserved.

Designed and Implemented by HM.

Water level detecting is critical in drums and boilers and other steam-raising systems since steam content inhibits accurate level control. There is the possibility of drum level falling below set-point, consequently the boiler can run dry, while if the water increase to higher level than set-point, wet steam enters downstream sections.

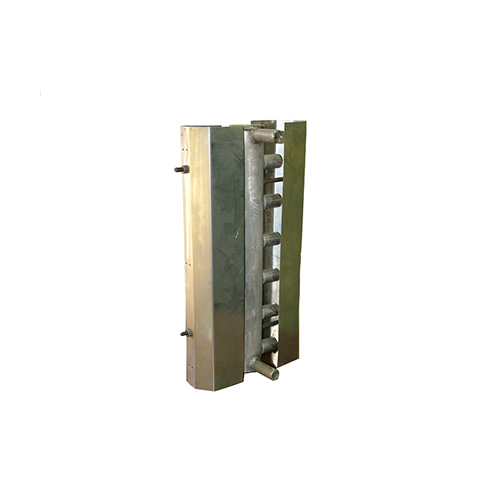

Hydra step water/steam monitoring systems are electronic gauging systems consisting of a water column which is connected to the drum, water enters the column from the vessel and by electrode signals based on the conductivity principle, the level of water is measured and monitored. This system is an alternative to water level gauges on boilers, giving a more reliable level indication than conventional visual gauges.

Continual boiler water level measurement is a key to reliable operation and safe process control. Eratech hydra step level monitoring systems can best accomplish such measurement, our Hydra step monitoring solution is ideal for controlling the challenging condition of high pressure and temperature boilers.

Containing a water column with up to 32 electrodes, remote display and control unit, Eratech hydra step monitoring systems are designed and manufactured in accordance with international standards.

Features and Benefits

Applications

ERATECH hydra step systems can: